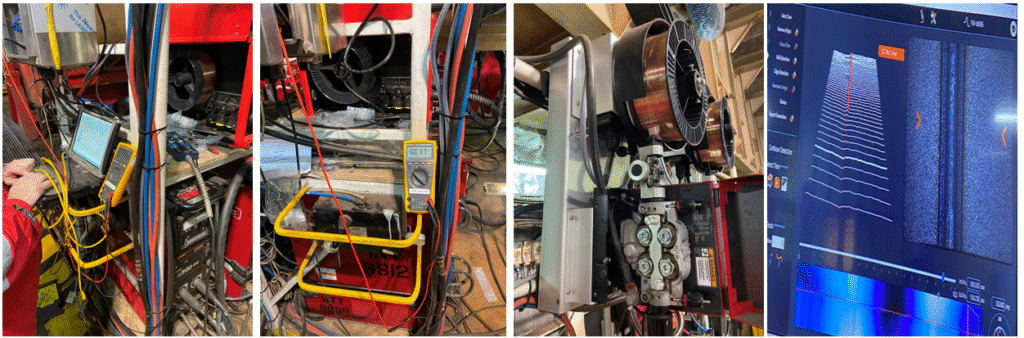

Deals in Welding Engineering & Inspection

Welding Design review, Welding advice on Welding codes & standards (API, ASME, DNV, ISO, BS, AS), Selection of right welding processes / techniques / consumables, Welding qualifications requirements for onshore fabrication and offshore Installations, welding / consumable / material selection inline to design / project spec requriments. Welding Inspection and welding repair analysis

Portfolio

Welding Engineering & Iinspection expertise in offshore & onshore construction industry globally, 20 years experience in welding engineering in pipeline & stuctures in all fields onshore & offshore industry.

Industries Served

Oil & gas (onshore & offshore), mining & petrochemical, Defence, construction

Contact ArcWeldEng – info@arcweldeng.com.au / +61423701750

Looking forward to support all your needs in welding engineering and Inspection discipline